What Are Calibrated Colored Stones?

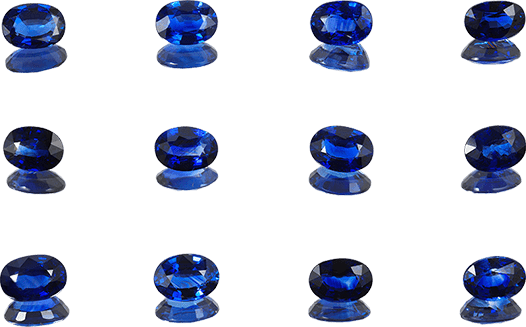

Calibrated colored stones are gemstones that have been precisely cut to standardized dimensions and shapes. Unlike free-size gemstones, which come in varying sizes and require custom settings, calibrated stones adhere to specific measurements. This standardization allows them to fit seamlessly into pre-made settings, streamlining the jewelry manufacturing process. Commonly calibrated gemstones include rubies, sapphires, and emeralds, prized for their vibrant colors and durability.

Importance of Calibrated Sizes in Rubies, Sapphires, and Emeralds

Efficiency in Production

Using calibrated colored stones significantly enhances production efficiency:

- Mass Production: Manufacturers can produce settings in bulk, confident that calibrated stones will fit perfectly. This eliminates the need for custom adjustments for each gemstone.

- Time-Saving: Standard sizes reduce the time spent on modifying settings, allowing for quicker assembly and faster time-to-market.

Design Practicality

Calibrated stones offer unparalleled design flexibility:

- Mix and Match: Jewelers can easily interchange stones and settings, creating diverse designs without altering the fundamental structure.

- Consistency: Standardization ensures that every piece meets the same quality and aesthetic standards, essential for brand reputation.

Unified Industry Standards

The adoption of calibrated colored stones creates a common language across the industry:

- Collaboration: Cutters, gemstone dealers, designers, jewelry brands, manufacturers, and setters all operate around the same specifications.

- Simplified Communication: Clear standards reduce misunderstandings and errors, improving overall efficiency.

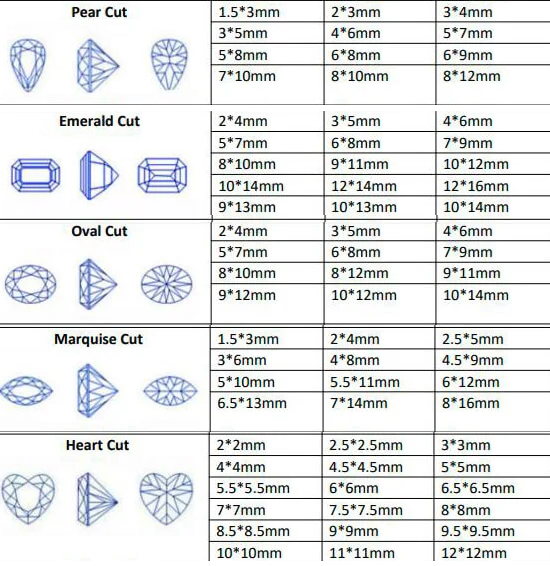

Standard Shapes and Sizes

Calibrated colored stones come in various popular shapes and sizes to meet diverse design needs:

- Rounds: Sizes typically range from 1mm to 10mm in diameter.

- Ovals: Common sizes include 6x4mm, 7x5mm, and 8x6mm.

- Emerald Cuts: Standard dimensions like 6x4mm, 7x5mm, and 8x6mm are prevalent.

- Marquise and Pears: Available in sizes such as 5×2.5mm, 6x3mm, and 8x4mm.

These standardized dimensions allow for easy integration into a wide array of jewelry pieces, from rings and earrings to pendants and bracelets.

Challenges in Calibrating Colored Stones

Despite the advantages, calibrating colored stones like rubies, sapphires, and emeralds presents several challenges:

Variability in Rough Material

- Inclusions and Color Zoning: Colored gemstones often contain natural inclusions and variations in color, making it difficult to cut them to standard sizes without sacrificing quality.

- Optimal Color and Clarity: Achieving the desired hue and transparency while adhering to calibrated dimensions requires expert cutting and can limit the availability of high-quality stones.

Yield Loss

- Material Waste: Cutting gemstones to standard sizes can result in significant loss of the rough material, increasing the cost of the finished stone.

- Cost Implications: The reduced yield from the raw gemstone translates to higher prices for calibrated stones compared to free-size counterparts.

Quality Consistency

- Natural Variations: Ensuring consistent color saturation, clarity, and cut quality is challenging due to the inherent differences in each gemstone.

- Supply Limitations: High demand for consistent, high-quality calibrated stones can strain supply chains, leading to shortages or increased costs.

Customization vs. Standardization

While custom-designed jewelry retains its allure, calibrated colored stones offer practical benefits:

Advantages of Calibrated Stones

- Affordability: Mass production of settings lowers manufacturing costs, making jewelry more accessible to a broader market.

- Consistency: Standard sizes ensure uniformity across product lines, crucial for brands focusing on signature styles.

Benefits of Customization

- Unique Designs: Free-size gemstones allow for one-of-a-kind pieces tailored to individual preferences.

- Artistic Freedom: Designers can create bespoke settings that highlight the unique characteristics of each stone.

Pricing Considerations

- Cost Savings: Although free-size gemstones may be 20% to 40% cheaper than calibrated stones, they incur additional costs in custom design and manufacturing.

- Production Efficiency: Calibrated stones reduce the need for custom mountings, lowering overall production costs despite the higher price per stone.

- Value Proposition: Clients may pay slightly more upfront for calibrated stones but benefit from the longevity and consistency of the design.

Limitations and Industry Adoption

Despite widespread adoption, challenges remain:

- Knowledge Gap: Some jewelry manufacturing hubs have not fully embraced calibrated colored stones, leading to mismatches between stone availability and setting dimensions.

- Sourcing Difficulties: Clients purchasing pre-made mountings from trade shows may struggle to find stones that fit non-standard settings, negating the initial cost savings.

- Professional Design Advantage: Working with experienced designers and manufacturers who understand calibrated stones ensures a seamless process and a final product that meets expectations.

Conclusion

Calibrated colored stones like rubies, sapphires, and emeralds play a pivotal role in modern jewelry manufacturing. They offer a harmonious blend of efficiency, consistency, and design flexibility, benefiting everyone from industry professionals to end consumers. While challenges exist in calibrating these precious gemstones, the advantages often outweigh the drawbacks, particularly for mass-market jewelry production.

By embracing calibrated colored stones, the jewelry industry can continue to innovate and meet the evolving demands of consumers, all while maintaining the timeless allure of these exquisite gems.